Working Pressure 15bar max.

Robust Construction

High performance screw compressors, air cooled, oil lubricated with compact cast-iron unit (encapsulated screw air end), providing leak-free operation and long-lasting performance.

The compact unit incorporates:

Screw air end with heavy-duty bearings and large diameter rotors, ensuring high efficiency and long service life, Intake valve, Intake Air filter, Centrifugal Air-Oil separation system with coalescing element resulting in oil carry-over less than 2 mg/m3, Oil filter, Oil receiver, Oil thermostat, Safety valve, Maintenance valve.

Highly Efficient Cooling

Oversized aluminum Air – Oil cooler, ensuring continuous operation even at high ambient temperatures.

Centrifugal condensate separator with automatic drain.

Independent cooling fan motor.

Optimal Control System

Paramina Digital Controller drives, controls & protects the compressor, ensuring safe operation and proper maintenance.

Safety device protecting against voltage failure & incorrect phase rotation.

Analogue safety & operating pressure sensors

24V secondary voltage providing safety during routine operation

Star/Delta Starter system

Electric motor Class F, IP55, IE3-4, 400-440V/50-60Hz, with overload protection

Simple Maintenance

Easy and rapid service access, through large doors (openings)

Low Noise Level / Vibration

Silent operation through highly efficient soundproofed enclosures.

Build-In anti-vibration control

Automatic belt tensioning system

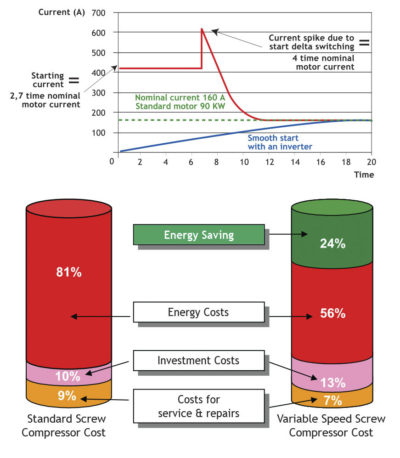

Variable Speed Inverter

- Saving in energy consumption.

- Smooth motor starting with zero over current.

- Continuous speed variation to achieve the exact required

air volume. - Constant network pressure (± 0,1 bar).

- User controlled selection of the network pressure (variable

adjustment between 5 and 13 bar). - Avoiding unload times (energy efficient).

- Reduction of unload cycles.

- No Load/Unload switching to ensure less stress to the

machine. - Harmonic filters and sensing protection device.

- Constant Power Factor.

- High Efficiency of the moror.

Fixed Speed (FS) &Variable Speed (VS) Models

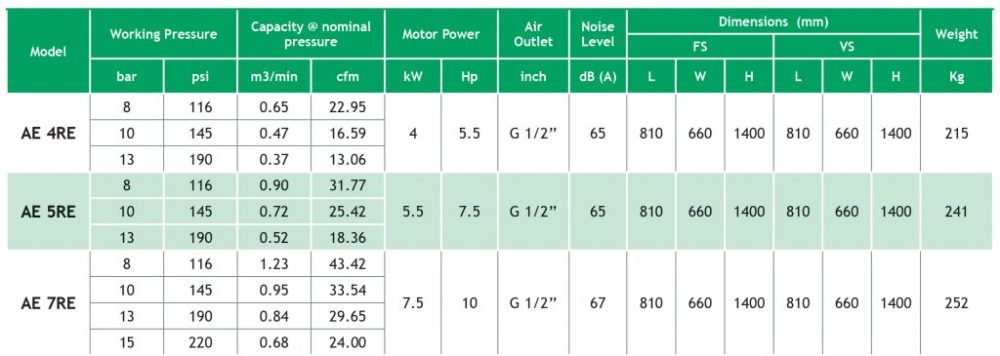

AE 4RE – 7RE

AE 11RE – 15RE

AE 18RE – 30RE

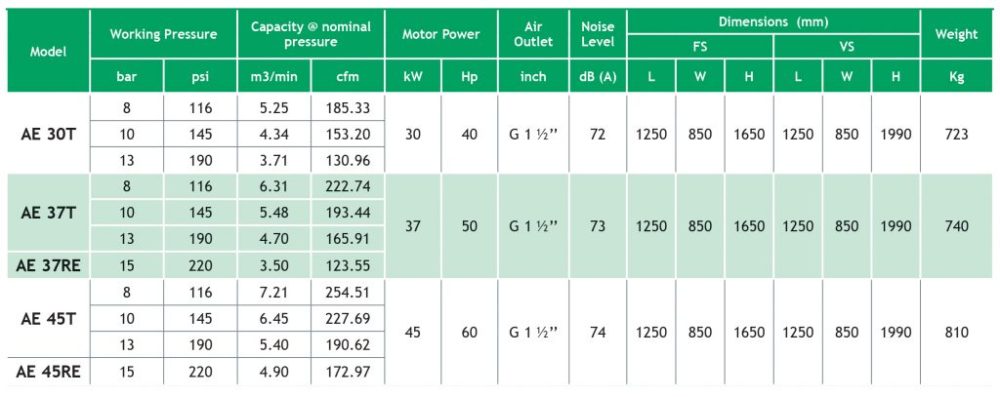

AE 30T – 45T & AE 37RE – 45RE

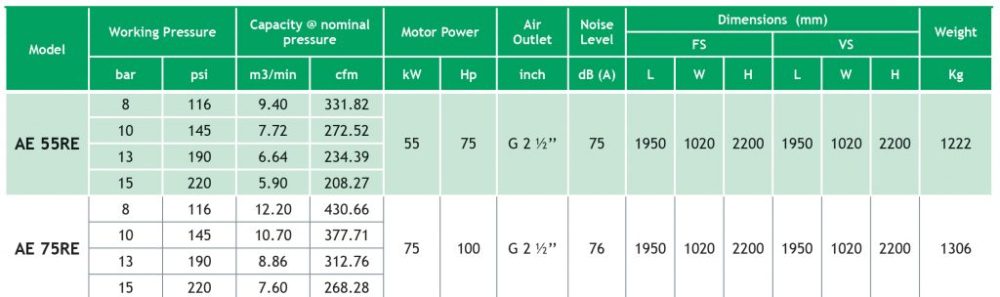

AE 55RE – 75RE

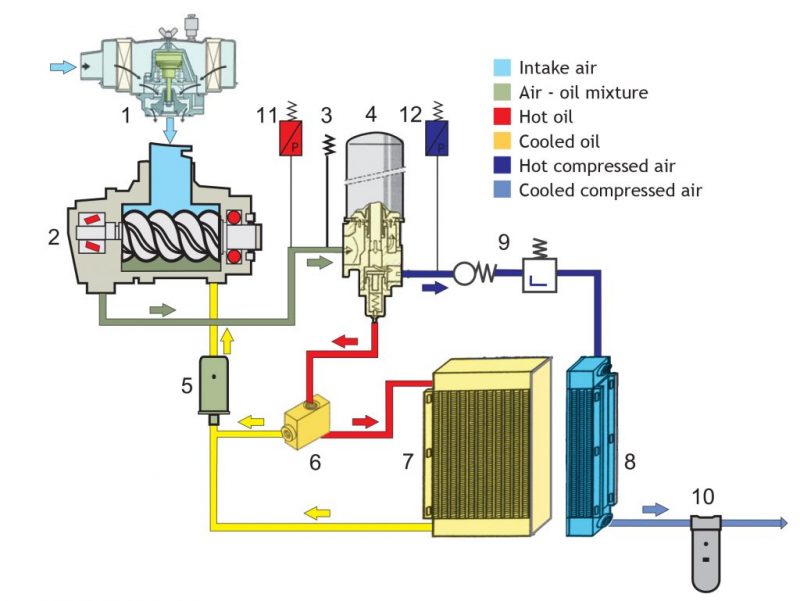

Flow Diagram

2 Screw Air End.

3 Safety valve.

4 Air/Oil separator.

5 Oil filter.

6 Oil thermostat.

7 Oil cooler.

8 Air cooler.

9 Maintenance valve.

10 Water separator.

11 Safety pressure switch.

12 Working pressure switch.